Guest Post by Pat Friedlander

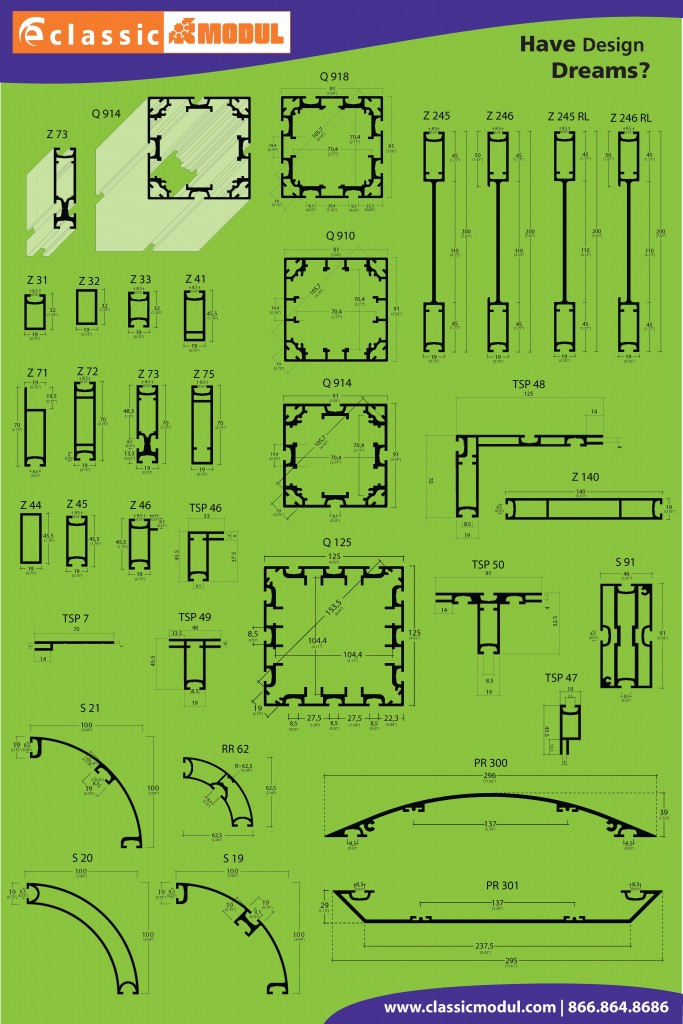

When I was new to this industry, I heard the word “Octanorm” bandied about as if it were the last ditch attempt for stingy exhibitors There was no design consideration — just how many panels and how many uprights.

However, on my first trip to EuroShop some 20 years ago, I was stunned when I walked into Hall 9 and saw the Octanorm corporate exhibit. EuroShop opened my eyes. U.S. was unique in advocating box-frame exhibits, exhibits that were crated and stored in warehouses around the country. It was apparent to me that US exhibits were different. They looked stodgy and boxy by comparison.

Systems and the Rest of the World

Between Dusseldorf and Chicago, I became a convert to systems. They looked cool, they allowed for fresh designs, and they were flexible — not hallmarks of box frame construction. Soon after, I invited my friend Kerstin Mulfinger from Burkhardt Leitner to speak at HCEA’s annual meeting about systems.

As various systems proliferated, bits and pieces started to appear on U.S. show floors. Yet the differentiation persisted that there were custom exhibits (i.e., box frame) and there were portable modular systems — with “systems” viewed as a commodity.

What is a Custom Exhibit?

Custom Exhibits, as the industry generally uses it, is a relic. Today the distinction is anachronistic. Using the term “portable modular” ignores the fact that modularity is not limited to any one type of construction — portable, custom, hybrid, etc. Modularity is related to configuration, not to building materials.

At an EDPA ACCESS 2015 session, I said, “It’s time to de-commodify systems and redefine what we mean when we say a custom exhibit.” It turned out I wasn’t alone. “Modular components and systems are no longer a commodity item,” said Jay Burkette, vice president, Expo Displays, “but represent building blocks, increasingly used by traditional exhibit houses as an effective way of helping design, manage, and maintain their client’s exhibit properties.”

At an EDPA ACCESS 2015 session, I said, “It’s time to de-commodify systems and redefine what we mean when we say a custom exhibit.” It turned out I wasn’t alone. “Modular components and systems are no longer a commodity item,” said Jay Burkette, vice president, Expo Displays, “but represent building blocks, increasingly used by traditional exhibit houses as an effective way of helping design, manage, and maintain their client’s exhibit properties.”

According to Debbie Parrott, president, Highmark TechSystems, “Some designers are predisposed to think that modular systems should only enter their design tool kits when they are working with an especially cost-conscious client. For those designers, low-cost and creativity are mutually exclusive and systems limit their creativity. This short-sighted view shows a lack of understanding of the realities of our industry and the needs of program clients.”

“Large clients are program clients who benefit from exhibit designs that offer versatility, reconfigurability, fast installation and dismantle – exactly what modular systems address. This perspective also shows a naiveté about the design trends in the global exhibit marketplace where modular systems are used for exhibits that are stunningly creative, brand-distinctive, highly functional, and cost and time efficient. Designers in our industry need to be knowledgeable on this front, and the challenge for those who are modular system proponents is to educate and show designers both the inspiring possibilities and the compelling business case.”

How Do YOU Define “Custom Exhibit”?

Seems to me that we need to arrive at a new definition of “custom exhibit.” If the definition is not about construction methods and materials, perhaps it’s about marketing. What are the goals and objectives of the exhibit program? How does the exhibit fulfill and meet those goals? And about the exhibit: Is it rental? Is it purchased? Should we differentiate? We plan to continue this discussion at EDPA ACCESS 2016, but in the meantime, I would love to hear your thoughts on this.

Pat Friedlander

pat@word-up.com

773-230-9989

Bio:

Pat Friedlander is a marketer, trainer, and writer in the exhibit industry. She has spent many days and nights on the trade show floor, and has lots of advice about shoes. She has received the HCEA Distinguished Service Award and the EDPA Hazel Hays Award. She lives in Chicago and often answers to Grandma Pat.

[subscribe2]