Guest Post by Dave Brown, Optima Graphics

When Neanderthals Walked the Earth

My first exposure to Silicone Edge Graphics (SEG) was in 2002. At the time, we (Optima) were using a foam/rubber gasket to finish fabric graphics. The gasket (similar to screen door material) was an aesthetic step forward from Velcro since it helped to remove ripples and waves in a fabric graphic, but it was not a viable long-term solution. In early 2003, Optima was approached by AIT. They were promoting an improved graphic attachment using a stretchy silicone material that could be tucked into a channel or systems groove on an engineered aluminum frame, like Octanorm or MODUL. I vaguely recall that they were selling frames as well, but don’t quote me on that.

During that same time frame, several truss suppliers were offering a “truss clip” option where an 18” section of aluminum channel would snap onto the individual truss rails. A magnet was sewn to the graphic, so it could be secured within the truss clip. There was nothing special about the magnet other than its dimensions were perfect for sewing it to the fabric and then tucking it into the truss clip. Functionally a shim. However, the magnet was impractical for shipping purposes.

With the ever-present desire to cut exhibit program costs, many “early adopter” exhibitors and exhibit houses were looking to fabric graphics as an option. Fabric or dye-sublimated textile graphics had two immediate advantages: they reduced the overall weight of an exhibit and they could be folded for compact shipping. But the Velcro and truss clip option each had aesthetic and practical flaws.

The Rise of SEG

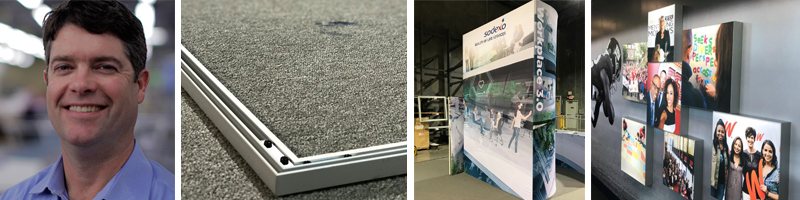

Entering 2005, Silicone Edge Graphics were moving more mainstream, and our very own Mary Mueller coined the term SEG. Heck, we even tried to trademark it, but the US Patent Office claimed it was too generic (but “three peat” could be trademarked. Hmmmm?). By mainstream, I mean that SEG was being incorporated into display hardware, wall-mounted frame solutions, and custom exhibits.

As time progressed, SEG became a true building material, and fabric now clads the exterior of exhibits in the same way Canyon Blue Formica or Tempo loop did in the early 90’s. Customers want their visual message and presence maximized in their exhibits, and as dye-sublimation has progressed so has the boundaries of SEG. It is not uncommon to see a single 10’ x 20’ SEG fabric graphic whether backlit or non-backlit that’s as stunning and real as a Lambda print. A handful of companies have incorporated machinery that will produce a single graphic that’s 15 ft. in width, and the industry has been the beneficiary of R&D from many different perspectives. For example:

Backlighting. At Optima, we have launched three different backlit materials in the last 11 months, and our suppliers keep sending us a steady stream of potential new materials to test.

Backlighting. At Optima, we have launched three different backlit materials in the last 11 months, and our suppliers keep sending us a steady stream of potential new materials to test.- Opacity. Fabric may have been great for packing and hanging, but prior to 2013, there were functionally no opaque options. The blocker game is over because numerous opaque options exist and are ideal for trade show graphics. Eliminating blockers reduces installation time and cost. We can all cheer for that!

- Stretch / Pliability. Installing SEG is, good bad or indifferent, a bit of an art form. A material that stretches east – west vs. east-west and north-south is a big deal because the added pliability reduces the artistic install talent needed by the end client or hired labor. “I have done this a million times” does not perfectly translate to “You are really good at it.”

- Wrinkles. Let’s not mince words, Wrinkles suck! I get it. Paying as much as $250 an hour for Sunday OT steaming is unappetizing to any exhibitor.Here’s a snippet from an actual conversation I had this spring, “Sorry I am late. My shirt was a mess from packing, so I had to touch it up with the iron.” Fast forward to, “We arrived at the booth and one of the graphics was all wrinkled, so we had to steam it. Why do we need to do that? We should not have to do this” Logically, you know that a shirt (piece of fabric) needs to be ironed to eliminate wrinkles, but a fabric graphic should be impervious to similar wear and tear. Trust me, the holy grail of dye-sub fabric graphics is a 100% wrinkle-free material. This is and has been a R&D priority for years.

- Flame Retardant (FR). Optima and many other high-quality providers will not sell an SEG dye-sub fabric graphic that is not FR. However, the FR treatment can increase the wrinkle factor or wrinkle-ability. Selling a NON-FR fabric is just plain stupid. Can you imagine ALL the instances where exhibitors are informed that all their fabric graphics need to be removed because they are unable to supply a FR certificate, and/or the material fails an onsite test? That is the stuff of lawsuits. It’s not worth it. Yet, there are instances where low-cost providers take that risk without informing the customer.

The Future of SEG

If the key ingredient in SEG is simply the attachment element (various rubbery / reasonably stretchy / reasonably firm 2.3mm x 7mm x 1mm-ish strips), then the sky is the limit. We have already progressed through print clarity (print resolution, density, color gamut via equipment and print technology), textile opacity, textile transmissiveness (backlighting), and ideal size of material.

If the key ingredient in SEG is simply the attachment element (various rubbery / reasonably stretchy / reasonably firm 2.3mm x 7mm x 1mm-ish strips), then the sky is the limit. We have already progressed through print clarity (print resolution, density, color gamut via equipment and print technology), textile opacity, textile transmissiveness (backlighting), and ideal size of material.

A Prediction: LED incorporation into the textiles will progress from experimental to routine and full digital textile is only a few years away. Envision a wall frame with an SEG monitor installed at any size you want. A 10 x 20 inline that conveys your client’s dynamic message, creates and morphs from one environmental engagement to the next, and during breaks on the show floor – you can watch your favorite Family Guy, episode. AND the whole thing fits in a single airline shippable case.

It’s coming sooner than we all think.

Dave Brown

dsbrown@optimagfx.com

Dave Brown is the VP of Sales at Optima Graphics. We all know and love Dave, so a long, detailed bio isn’t really necessary. And, yes, we all have a memorable Dave Brown story.