Engineered Aluminum Extrusion

Aluminum Extrusions Offer Few Limitations

Written by Exhibit City News

Not all aluminum extrusions are equal. Some have limited uses, flexibility and structural weight tolerance. But no matter what vision an exhibit designer has for the layout of the booth, there is an engineered aluminum extrusion that can help bring it to life.

Exhibit City News recently interviewed three trusted sources in the extrusion industry to get a comprehensive look at the benefits, trends, and technology that make up this growing segment of exhibit design.

Speaking on behalf of ClassicMODUL, a supplier of aluminum extrusions that offers comprehensive design and engineering support, is Mel White, vice president of marketing and business development.

Representing Octanorm USA, a leader in the extrusions market since the company was founded in 1968, is Norm Friedrich, president.

Our final industry professional, Xavier Decludt, is the president of AGAM Group, a worldwide supplier of aluminum modular display systems.

ECN: What are the benefits of using an extrusion-based exhibit construction system?

Mel White, ClassicMODUL: Unlike a traditional portable/modular system or custom (wood-based) exhibit, extrusion exhibits have few, if any, limitations in construction, appearance and modularity. Plus, they play nice with existing “systems” or custom-built displays as either a component or as structure. Most engineered extrusion systems include hundreds of aluminum profiles, from square to ovals, and from round to rectangles. The sheer flexibility allows designers to create large architectural structures that either showcase or minimize the aluminum structure.

Norm Friedrich, Octanorm: The benefits are numerous and depend on each company’s individual needs. Over the past 20 years, these aluminum systems have developed into design programs rather than construction elements. The variety of angles, curves, connections and accessories are so extensive it allows for custom design even when budgets are tight.

Xavier Decludt, AGAM Group: Extrusions can be used to implement any design or feature element can be imagined and recent design trends are making it a sought after solution for the modular industry. Extrusion can be integrated into existing material and be added on for a larger booth. Another major benefit of extrusions is a much lower operating cost for material handling, labor and freight.

ECN: How has the integration of fabrics/graphics changed over the last five years?

Friedrich: We’re not fabric experts, but we certainly know that the print quality on fabric has improved dramatically over the years, making it an excellent choice for large format graphics. What was once dull and grainy is now crisp and clear. Aluminum extrusion provides an ideal framework for fabric and has become the material of choice for many of those who are searching for a large dynamic presence with reduced weight and cost.

Decludt: Many conventional graphics are being replaced by silicone edge graphics (SEG) and new extrusions are always in development. Fabric is lightweight, durable and portabe, which reduces the amount of metal that is visible. When fabrics are folded, they take up less storage space. When this is combined with the slim profile of extrusions, exhibits become a lot easier to handle.

White: There have been two significant trends, both from Europe. Fabric graphics are getting bigger and those graphics are increasingly SEG. There has been a gradual shift toward showing less aluminum without losing the benefits of aluminum structures, particular in island exhibits. The same trend can be seen in signage. Whether backlit or non-backlit, event and tradeshow signs are shifting to fabric. It’s lighter, more durable, and as color vibrant as direct print.

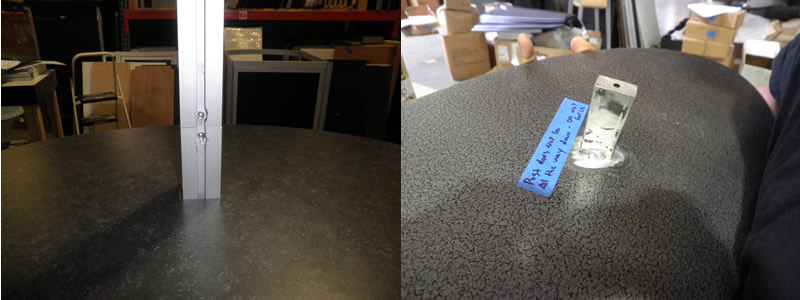

MOD-1276 iPad Kiosk

ECN: What new products and design solutions is your company offering?

White: You can’t be on the cutting edge right now without a variety of SEG profiles and SEG designs. We offer 15 unique profiles that allow clients to build anything from small signs to large islands using silicone edge graphics. Our new SEGUE design line includes over 30 exhibit designs, which shows that SEG can be affordable, sexy and portable/modular.

We’re seeing the integration of traditional custom components into extrusion designs in trade show, retail and event applications. Retail applications are booming, and retailers are looking for answers that allow for modular flexibility where they can redefine the space every six months rather than every five years.

Kiosks integrating iPads, cell phones, readers and other technologies have been in demand. We’ve created extrusion solutions for all these.

Decludt: Pliko is a no-tool folding frame that features a minimalist design and clearly defined edges. The 108-inch by 92-inch graphic area maximizes graphic exposure and the slim frame structure virtually disappears.

We also have a new FH 1490 extrusion system that can accommodate graphics inside and outside the cubes. If you hang such cubes, you double your graphic exposure without any additional hardware costs, and if you suspend such cube, your free valuable floor space is available for product presentation and customer interaction.

We have also developed the FH hybrid system, which has the ability to use a fabric frame or convert it for to a hard panel without acquiring new aluminum.

Friedrich: Extrusion systems in general have evolved tremendously over the years and we are all busy creating new solutions to keep designers on the cutting edge. At Euroshop and Exhibitor this year, we introduced 21 new products. These include new and innovative ways of providing shelving, attaching LCD monitors, creating walls, building lightboxes, etc.

ECN: How is business and demand for your extrusion-based exhibits?

Friedrich: We have felt the effects of a weak economy just like everyone else but the demand for extrusion based exhibits seems to be quite steady. While many are re-using the properties they already own (one of the side effects of a material that lasts forever), it shows a lot of creativity on the part of business owners by making the most out of a product while keeping investment at a minimum. What better way to remain competitive than by using your existing inventory in new and exciting ways?

White: Excellent. Classic Exhibits and ClassicMODUL Aluminum Extrusions offer clients two distinct business models. This has allowed us to tap into demand from two unique avenues.

We’ve learned that location matters when it comes to ordering aluminum extrusions. As a result, we’ve established metal depots in three U.S. locations: Portland, Ore., Cheshire, Conn., and Birmingham, Ala. MODUL aluminum extrusion is also readily available throughout Europe and the Middle East.

Decludt: Based on demand for our extrusions, we can tell that the industry is turning around.

ECN: How has technology affected the extrusion industry?

Decludt: We have invested heavily during the past three years in building, machinery, equipment and software. We are one of the very few manufacturers able to offer a wide array of services to the trade, with more than 50 machines under one roof. Our customers come to us with unique design requirements to stand above the crowd, and we are able to respond quickly and efficiently to most of their challenges, giving them the competitive edge needed in today’s market place.

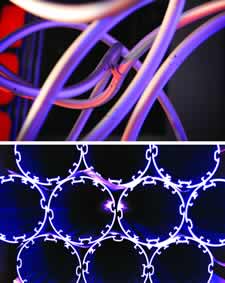

Friedrich: Technology has certainly has a positive impact on aluminum systems because they are so adaptable. The latest technologies in graphics, audio, video and lighting can easily be incorporated into these systems. I think it’s important for people to realize that aluminum systems are designed as a means to incorporate custom elements and technology falls into that category as well.

White: You adapt or you die. Obviously, LCD and plasma screens are commonplace in nearly every display, from table tops to islands. The trick is to create solutions that do more than simply hold a monitor. We’ve designed workstations, kiosks, counters and displays that integrate monitors into the overall visual presentation. The pace has quickened. When something new comes out, such as the iPad, for example, you can’t wait. You have to design multiple solutions, see what appeals to your customers, and then adapt and refine those solutions.

ECN: Can an extrusion system be used to build just about any design a client is looking to create?

White: No question at all!

Decludt: Extrusions are not always the best solution to a custom design, but the modularity of Aluminum Systems reduces dramatically design and engineering costs, and time to market is essential – only a modular system in aluminum achieves that.

Friedrich: I may not be the best person to answer this question, but my completely biased answer is “of course!” We see a lot of crazy concepts in our engineering department and most of the time, we can find a solution that does not compromise the integrity of the design. The only time we may run into issues is with regards to structural integrity. But as long as everyone is open to some additional support either overhead or in the form of bracing, we can usually overcome those issues as well.

–Mel White

http://www.linkedin.com/in/melmwhite

mel@classicexhibits.com

For example, navigating your way through the exhibitor manual can be daunting. Recall the first time you read through that manual and attempted to complete those forms. It’s a nightmare. At one point, I asked Convergence if they knew how much electricity would be provided for their booth, which was the largest space in the show. Had we not asked, they would have had just enough juice to power a Crest Spinbrush or a cell phone charger.

For example, navigating your way through the exhibitor manual can be daunting. Recall the first time you read through that manual and attempted to complete those forms. It’s a nightmare. At one point, I asked Convergence if they knew how much electricity would be provided for their booth, which was the largest space in the show. Had we not asked, they would have had just enough juice to power a Crest Spinbrush or a cell phone charger.