Kevin Carty, VP Classic Exhibits

I love technology! But sometimes, I fear, we miss the basics, the commonsense in our effort to make things more efficient and streamlined — like what makes sense. For example…

Last week I met with a transportation company, one of the well-known Big TWO. At the beginning of 2015, this carrier introduced a slick handing system in their sorting facilities replacing the old system that required someone to manually check measurements on larger packages.

This new system uses calibrated lasers to scan a case or package to take the dimensions. It’s way cool! And from a business perspective I appreciate the time it saves as opposed to hand measuring each large piece. But that is where the cool factor hits a glitch.

Measuring Roto-Molded Cases

In our world, which includes portable, modular, and hybrid exhibits, we ship thousands of pop-ups, panel systems, counters, workstations, and component orders each year. Many ship in portable, durable, and reliable roto-molded cases. We know, as do you, that the first shipment better be perfect. You want that baby showing up looking new, case included. So many of us wrap those cases in heavy poly bags, heavy shrink-wrap, or some other protective packaging hoping the case looks as new as the exhibit it holds when the client sees it for the very first time.

In our world, which includes portable, modular, and hybrid exhibits, we ship thousands of pop-ups, panel systems, counters, workstations, and component orders each year. Many ship in portable, durable, and reliable roto-molded cases. We know, as do you, that the first shipment better be perfect. You want that baby showing up looking new, case included. So many of us wrap those cases in heavy poly bags, heavy shrink-wrap, or some other protective packaging hoping the case looks as new as the exhibit it holds when the client sees it for the very first time.

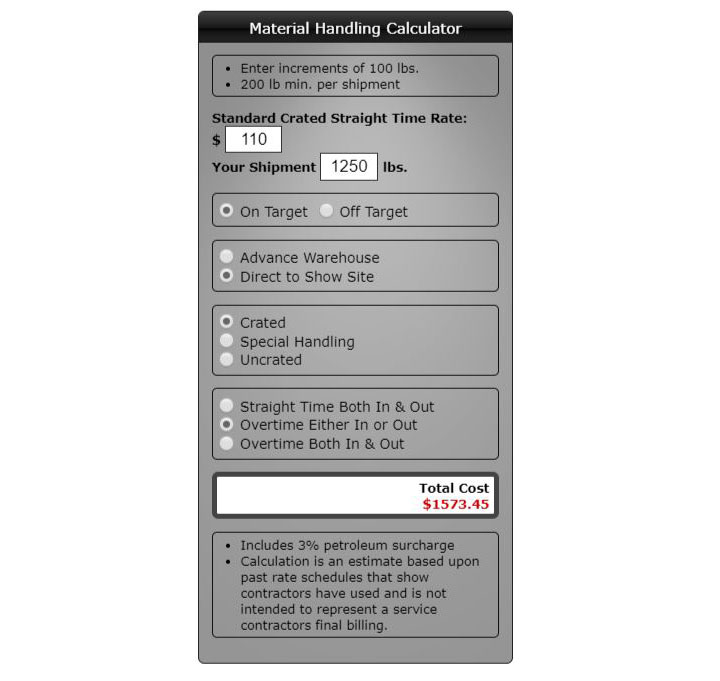

Well, this week I learned of a big flaw in the transportation companies new process/flow system that uses those cool lasers. It’s so good at calibration and scanning that it catches the very outermost dimension possible. Let’s say you packed a case in a protective heavy-duty poly bag, then taped and or heat sealed it shut at the open end. Well look at the photo. See down by the floor how the bag, not the case, is sticking out? When you account for that, your 26″ wide case just became 34″ to the new/cool scanner. Or look at the other photo. Say your client is shipping this from the show floor after their fifth use. They do everything right, including pulling the case straps really tight. But the tail on the strap is curled up like the picture. Now your 9″ deep case just became 13″ deep by the lasers standards.

I mention this up not as a complaint with the new, highly-efficient system. I understand why they implemented it. But these “new” potential dimensions just doubled your client’s cost to move that case because the case became “over-sized” in the eyes of the new laser machine.

I mention this up not as a complaint with the new, highly-efficient system. I understand why they implemented it. But these “new” potential dimensions just doubled your client’s cost to move that case because the case became “over-sized” in the eyes of the new laser machine.

To their credit, the freight company sent a rep to review our concerns, and they are giving our client a credit. But there is no way around this in the future. So I was told “you and your customers need to be mindful of this on all shipments.”

Back to my original point, and again not complaining, but sometime the latest and greatest technology cannot replace the common sense that comes pre-equipped in a human with a measuring tape.

I would encourage you all to take some heed to this story. It’s much more than just a little extra charge here and there on some shipments. It can double the cost of your shipments.

After a little bit of research I have found that it’s not just the big TWO that are moving, or have moved, in this direction. Many smaller transportation companies and even some regional carriers are looking to adopt similar systems.

Have a great weekend ahead!

Be well!

–Kevin

http://twitter.com/kevin_carty

http://www.linkedin.com/pub/kevin-carty/3/800/32a

[subscribe2]