From time to time, we are asked about our manufacturing process and quality standards. In other words, how do we ensure consistency, quality, and efficiency in a manufacturing environment that has to be responsive, time sensitive, and adaptive in a job-shop environment? In short, we are a “Process-Driven” manufacturing environment.

From time to time, we are asked about our manufacturing process and quality standards. In other words, how do we ensure consistency, quality, and efficiency in a manufacturing environment that has to be responsive, time sensitive, and adaptive in a job-shop environment? In short, we are a “Process-Driven” manufacturing environment.

Manufacturing Processes and Controls

Classic Exhibit’s production workflow is based on the lean manufacturing principles of process simplicity, cellular manufacturing, easily identifiable tripwires or control points, limited metrics, just-in-time material and process management, and ongoing team development. Defined individually, they form the basis of our collective process mindset to produce cost-effective products quickly while ensuring unsurpassed quality.

1. Process Simplicity

Manufacturing simplicity at Classic is a never-ending focus to eliminate all non-value added steps and procedures which improves throughput speed, improves quality and lowers costs. Based on just-in-time principles, it involves reducing in-process inventory lots, monitoring quality in-process rather than post-process, empowering line workers with key decision-making authority, perfecting repeatable tool setup and procedures, constantly scanning for tripwire points to identify and fix quality problems locally in the workcell, and incorporating team development into the daily workflow. This common sense approach is the responsibility of both Classic’s management and line workers, and they take unusual pride in contributing in the moment to its success.

2. Cellular Manufacturing

Classic’s work flows are centralized in circular work cells which eliminate wasteful inter-departmental material movement and routing, reduce work-in-process queues, optimize machine set up and usage due to just-in-time workflows, and promote individual worker pride in the quality of the cell output because they are empowered as decision makers for each production step. Further, all cell workers are cross-trained on all skill sets and work flows.

3. Process Control Tripwires

Process control tripwires are easily identifiable manufacturing control points that highlight a problem and trigger an immediate action to investigate the problem using more detailed metrics. Each cell worker is responsible for 3-6 tripwire metrics at any time, depending on the process step. This approach moves the focus away from inspecting each component post-process to verifying it is correct in-process and assumes that it is correct unless a tripwire highlights a problem. Most tripwires involve the fit and finish of the product and are obvious at any step in a components manufacture. Quality becomes the continuous responsibility of cell workers instead of being relegated to the tail end of production after substantial value has been added to a defective part.

4. Limited Metrics

The lean approach of using limited metrics is driven by the over-arching principle of keeping all lean approaches simple. The goal for Classic is to be able to monitor sophisticated control points using the line workers. In Classic’s case, very few close tolerance operations are verified using skill-based measuring gauges such as micrometers. Instead we guarantee close assembly tolerances using precision machined drilling and go,no go gauges. In the event of unusually challenging quality problems, we use statistical analysis control models to drill down to the root cause to correct issues and establish process controls.

5. Just-in-Time Material and Process Management

Classic’s cellular manufacturing is a circular process that focuses on building components as they are needed to avoid costly and space-hogging inventory back stocks. This approach requires close integration between Classic and our suppliers, who, as business partners, agree to make our raw materials available on short notice. The only exception is our custom aluminum extrusions that require minimum orders and a longer lead time, but even with those, we strive to have a continuous cycle of materials in the purchasing queue.

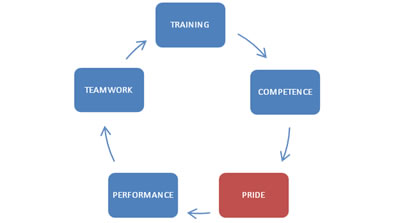

In the end, our quality and our predictable delivery schedule is the result of our dedicated work teams fully embracing our lean principles and adopting them as their own. Worker pride is the most critical element in the circular pattern that is the engine of our success.

Lastly, but most importantly, our worker tenure is unusually long-term which speaks both to our fun and supportive company culture and our employee’s enjoyment of the work they do. The result enables us to retain and build on critical skills and knowledge as we continuously improve our processes and develop new products. It also ensures that our production is done by team members who share Classic’s positive mindset and possess the technical skills to repeatedly produce high quality products.

–Mel White

http://www.linkedin.com/in/melmwhite

mel@classicexhibits.com

Classic Exhibits Network (LinkedIn)