If you’ve participated in a trade show recently, you’re very familiar with fabric graphics like silicone edge fabric graphics (SEG). However, not long ago, most trade show graphics were printed on a plastic, vinyl, or corrugated paper substrate. These had to ship flat in a box or rolled in a tube to protect them… and damage was common, even with careful packaging and installation.

Today, fabric graphics dominate as the primary graphic medium for trade shows. Largely for three reasons: (1) They’re lightweight, (2) Relatively indestructible, and (3) Are available in large formats up to 10 to 16 ft. wide. In this article, let’s explore how and why Silicone edge graphics dominate trade shows and events.

Understanding Silicone Edge Graphics: An Overview

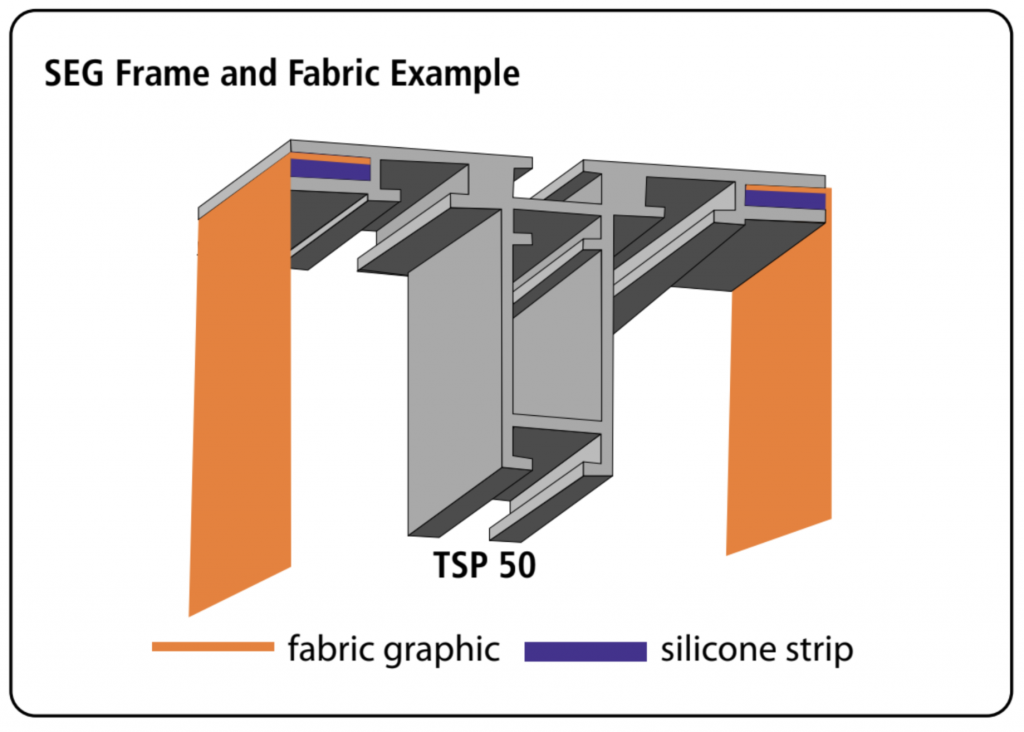

Let’s start with the basics. SEG is a high-resolution dye-sublimated fabric graphic finished with a thin silicone strip (or welt/gasket). The silicone strip is sewn directly to the edge of the graphic, and the strip is then inserted into a frame with a recessed groove.

The size of the graphic must be precise so the fabric is taut when installed in the frame. The result is a large format graphic that mimics the old-fashioned hard panel graphics commonly found on custom displays and interior spaces.

Dye sublimation is a versatile process for printing vibrant, long-lasting designs on fabrics, especially synthetic ones like polyester.

1. Design and Printing: It starts with a design, like a photo, pattern, or text, which is digitally printed onto special transfer paper using sublimation inks. These inks are unique because they can transition directly from a solid to a gas state, skipping the liquid phase.

2. Heat and Pressure: The printed transfer paper is placed on top of the fabric (usually polyester or a poly blend) and then fed into a heat press or calender. This applies intense heat and pressure, around 200°C (400°F) for 30-60 seconds.

3. Gaseous Transformation: Under this heat and pressure, the sublimation ink on the transfer paper transforms into a gas. This gas permeates the fabric’s fibers, creating a permanent bond. The ink dyes the fabric from within, rather than just sitting on top of it.

4. Cooling and Setting: As the heat press cools, the fabric’s fibers contract, trapping the gaseous ink permanently within. This results in a vibrant, high-resolution print that’s resistant to fading, cracking, and peeling.

Unique Features of SEG Fabrics

Overall, dye sublimation is a powerful and versatile technique for adding vibrant, permanent designs to fabrics. Its combination of high quality, durability, and softness makes custom silicone edge graphics a popular choice for inline and island trade show exhibits and retail graphics.

- Superior Fabric. The high-quality fabrics come in a variety of weaves, twills, and thicknesses for most backlit and non-backlit applications

- Versatile. Silicone edge graphics can be used on engineered aluminum extrusion profiles which are both lightweight and durable.

- Quality. The fabric undergoes a painstaking pre-inspection before the images are printed.

- Dye-Sublimation. Dye-sublimation graphics are vibrant and lightweight.

- Less Frame. SEG fabric graphics are the perfect choice when more graphics and less frame is desired.

- No Sew Line. Unlike bead or pole pocket finished graphics, the sew line is hidden within the extrusion providing a more finished look

- Eco-friendly Options. Fabric vendors are introducing more green options using recycled fabrics, which have the same benefits as traditional non-sustainable fabrics.

The Benefits and Applications of SEG Graphics in Trade Shows

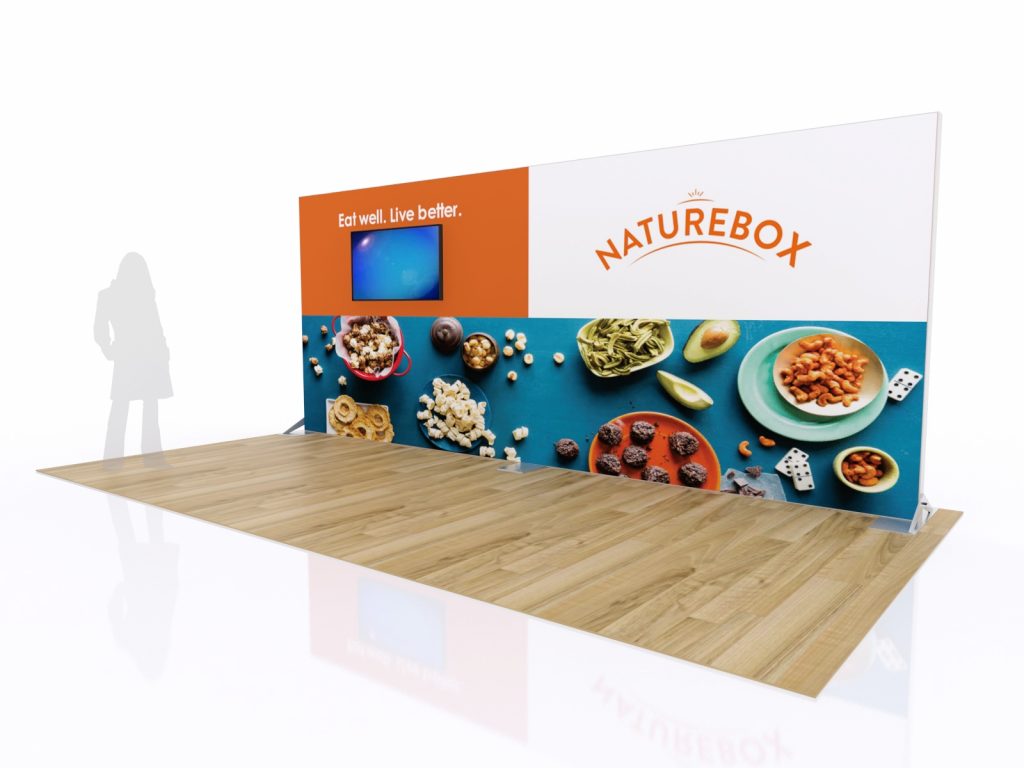

Modern and Visually Appealing: SEG graphics offer a sleek and frameless appearance, creating a more modern and high-end look compared to traditional signage. The fabric itself is smooth and wrinkle-resistant, further enhancing the visual appeal.

Easy to Install and Change: The silicone edges easily slide into the grooves of the aluminum frame, making installation a breeze. The lightweight fabric can be rolled or folded for storage and transportation, and graphics swapped out quickly and without special tools.

Versatility and Customization: SEG fabric graphics are ideal for a wide variety of applications, from wall murals and window displays to trade show booths and event backdrops. They can be custom-printed in any size, shape, or color, and can even be backlit for added impact.

Other Benefits Include:

- Storage and Shipping. Fabric is lighter than many other graphics and when folded neatly, take up much less space.

- Care. Fabric graphics can be washed and steamed and are as durable and long-lasting as traditional graphics.

- Lightweight. Larger graphics weigh less, perfect for draping or creating space definition.

- Cost. More image bang for the buck!

- Green. In addition to transportation and storage benefits, there is a growing list of fabric options created from recycled materials!

- No Glare. Fabric is the perfect choice for media walls or any backdrop that is being photographed or filmed.

- Versatility. SEG fabric can be applied to most displays or event structures.

- Less Visible Frame. The silicone edge means you see more of the graphic and less of the frame.

- Curves. Some aluminu extrusions can be curved. Ask about design options.

Why Customers Love SEG Graphics:

- Tight as a drum, vivid, flat fabric graphics replace hard panel graphics in custom displays.

- Highest quality look.

- Neatly finished corners.

- More visible graphics, less frame.

- Attached pull tabs ensure easy removal from the frame.

- Quick install and even faster breakdown.

- Improved storage, drayage, and shipping costs with fabric graphics

Choosing the Right SEG Fabric for Your Display

Like any fabric, there are materials meant for specific applications, like indoor or outdoor usage, qualities like durability, vibrancy, and lightweight properties, and, of course, overall quality. In some ways, SEG fabric is like clothing. There are fabrics meant to last for years and other fabrics meant to be tossed after a season.

When reviewing your options, take the time to ask your vendor to explain which fabric they’re using and the benefits, features, and warranty of that choice(s). There are two main types of SEG fabrics: knitted polyester and backlit polyester. Backlit polyester tends to be more expensive, durable, and wrinkle-resistant.

Other Considerations:

- Backlit vs. Non-Backlit Fabric

- Stretch vs. Non-Stretch Fabric

- Size. The typical maximum size of an SEG graphic (without a seam) is 118 inches wide. However, there are a few dye-sublimation printers that can print up to 188 inches.

- Build-in Blocker vs. Separate Blocker

- Folded vs. Rolled

Silicone Edge Graphics Frame: The Foundation of SEG

Silicone Edge Graphics require a frame with a channel to hold the sewn silicone welting that surrounds the fabric. Although the channel can be cut into wood or molded into plastic, the most common SEG frames are aluminum. Aluminum extrusions offer the benefits of light weight, durability, structure, and versatility. Depending on the vendor, there are SEG aluminum frames as wide as 8 inches and as narrow as ½ inch.

Engineered SEG aluminum can be cut, bent, and constructed into squares, rectangles, and even curves. The extrusion can also be powder-coated or anodized in hundreds of colors to match the most demanding design requirements.

Finally, aluminum frames have the extra benefit of endless recyclability. Aluminum frames recycled one week may be melted, formed into billets, and extruded into new extrusions a week later.

Maintenance and Care of SEG Displays

Most SEG fabric graphics should be folded and stored in a plastic bag. You may spot clean by wiping with a damp cloth. If it is necessary to wash the graphic and it is small enough, use a commercial-size front-loading washing machine. Wash on the gentle cycle, with cool water. Dry cleaning is NOT recommended.

To limit getting the graphic dirty during installation, keep the set-up area clean by using a drop cloth and wash your hands prior to set-up. You may want to consider purchasing inexpensive white cotton gloves. Wearing gloves while handling the graphic will minimize the transfer of dirt and oils to your graphic

Custom Silicone Edge Graphics from Classic Exhibits!

With SEG Fabric Graphics, you can dream BIG with your next trade show exhibit. Whether backlit or non-backlit, fabric graphics allow you to tell your story in ways unimaginable a few years ago.

For over 30 years, Classic Exhibits has been a reliable source of expertise for new and seasoned trade show marketers. The Classic Exhibits Distributor Network includes over 200 North American exhibit houses and display professionals. Find success on the trade show floor with an exhibit that reflects your marketing message. For more information, see www.classicexhibits.com and explore Exhibit Design Search or request a meeting with a Classic Distributor Partner.